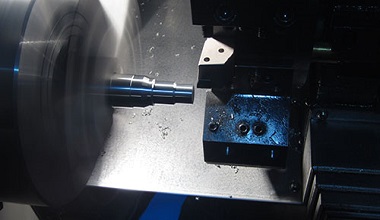

[Industrial Knowledge] 5 axis CNC horizontal milling machine operation precautions The 5 axis CNC horizontal milling machine and also uninteresting device appropriates for refining large and medium-sized parts as well as box-shaped components for rough and also great boring, milling and also other processes. The worktable is furnished with a 4x90 ◦ optical positioning device, which can satisfy the requirements of the U-turn handling of huge components. 5 axis CNC horizontal milling machine, as well as monotonous machine, appropriates for box-shaped component opening as well as aircraft machining with several processes, turning of outer round surface area, reducing of the annular groove in opening, tapping metric as well as inch strings, and so on. It also has the rectangular coordinate system and pole of CNC machine devices. Coordinate system and procedure function of shape handling. Due to the fact that the 5 axis CNC horizontal milling machine as well as the dull maker has high rigidity and also closed-loop discovery system, which can fulfill the requirements of ha